Silicone Mould-Making Tests

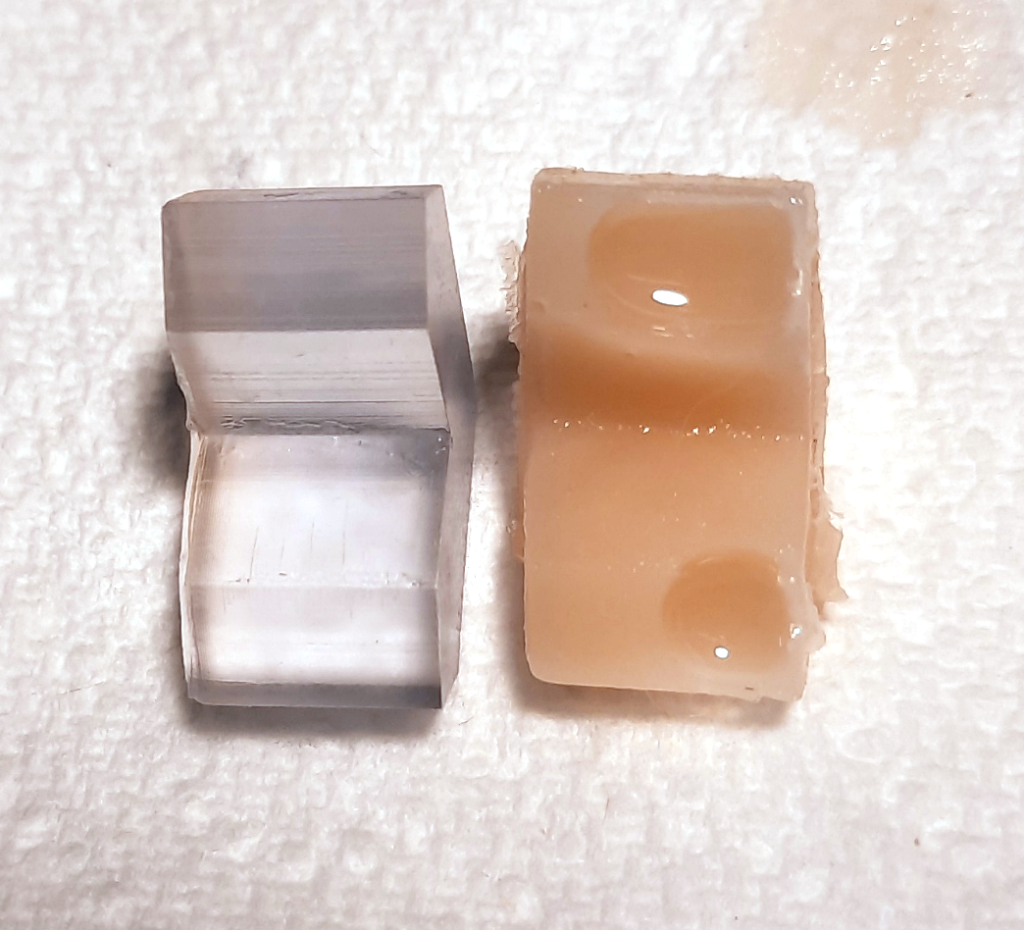

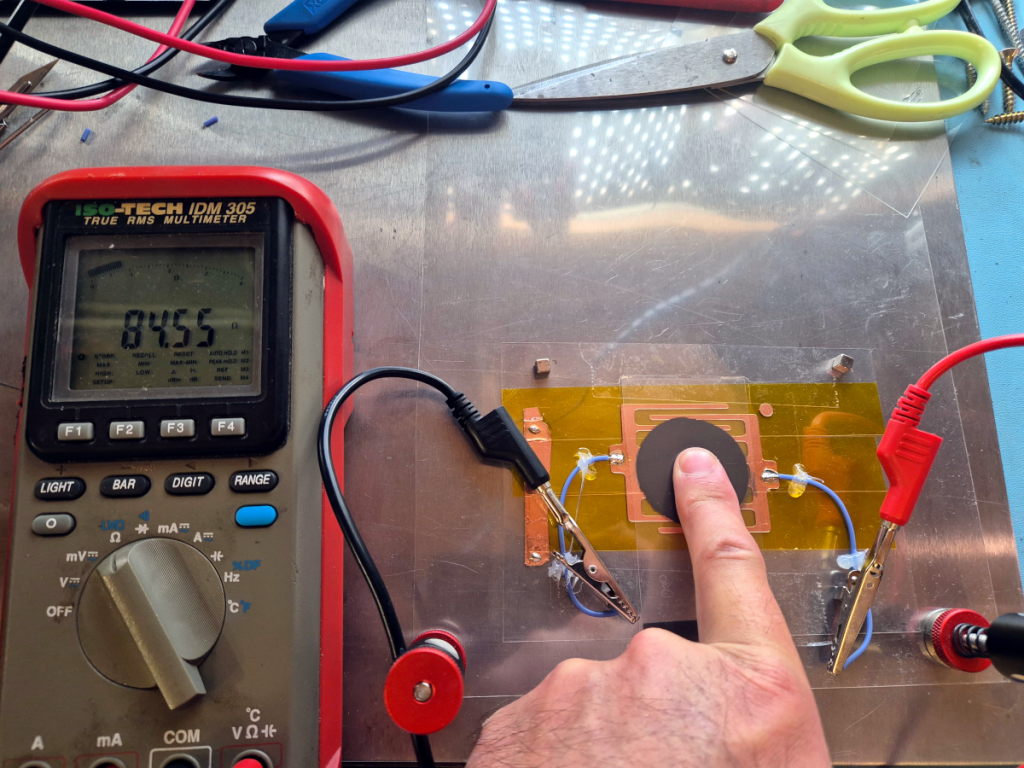

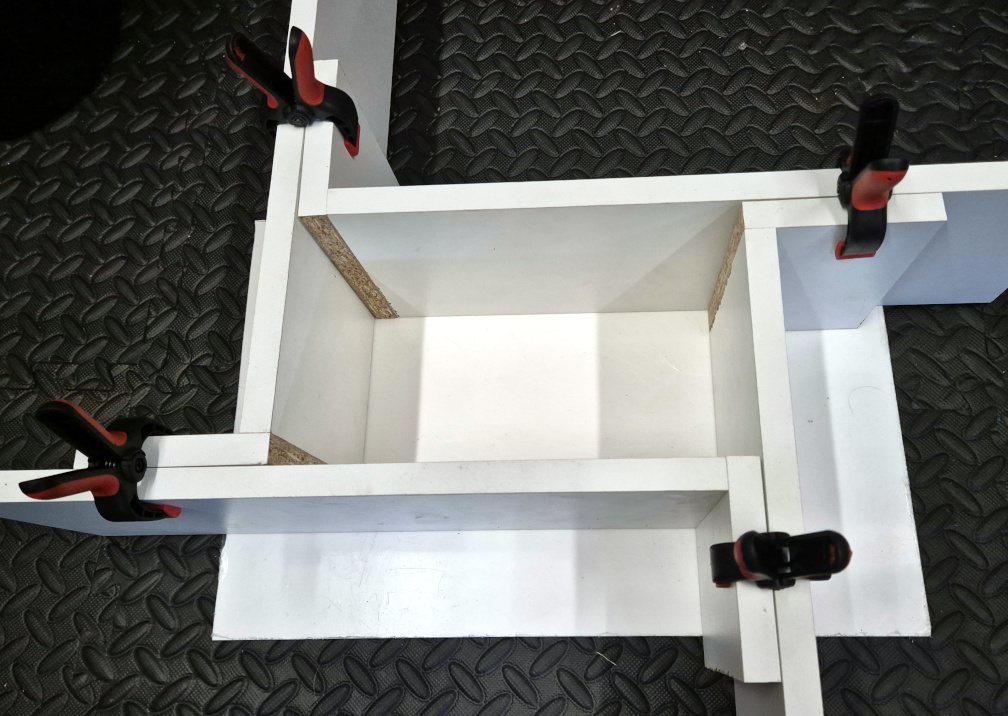

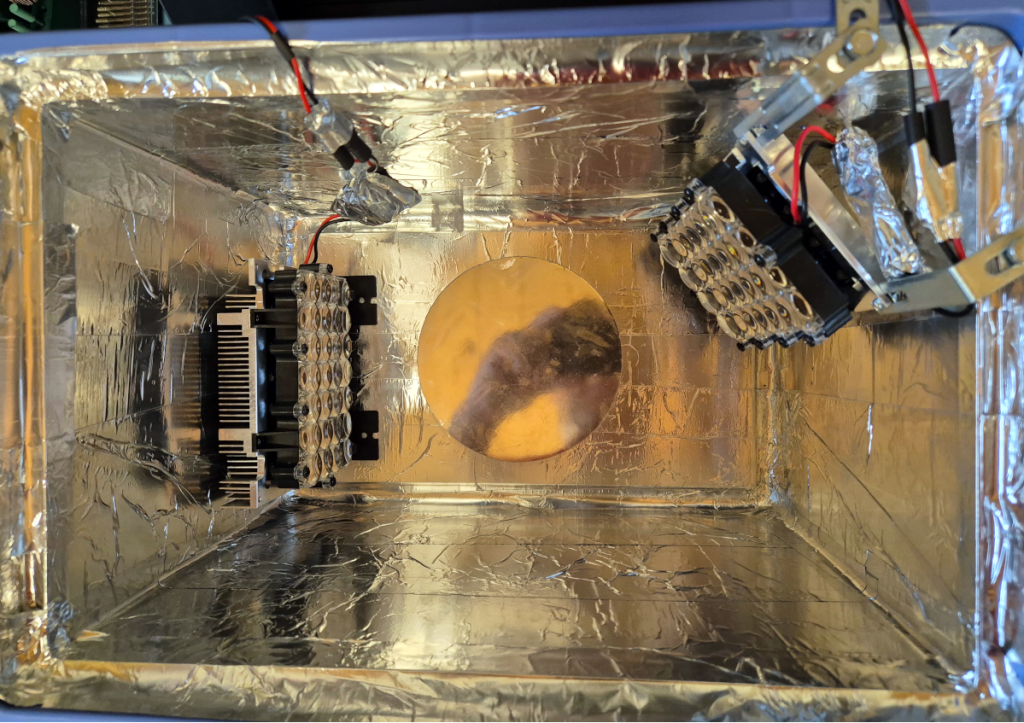

Introduction I need to develop rigid and flexible mechanical components for the ABSS project using 3D-printed masters. After some research, I found that a common method used by artists for sculpting involves creating moulds using silicone for subsequent casting. Silicone is suitable for this purpose because it has different flexibility grades and is inert. It […]

Silicone Mould-Making Tests Read More »